Sample Lead Time vs Production Lead Time: Why Fast Prototyping Does Not Predict Mass Production Timelines

When procurement teams evaluate suppliers for custom tech gifts—branded wireless chargers for a corporate event, power banks for an employee recognition program, or USB drives for a client giveaway—they typically begin by requesting samples. The supplier produces a prototype, the buyer inspects it, and if approved, the buyer places a production order. During the sampling phase, the supplier often delivers the prototype within 5–7 days, demonstrating their responsiveness and capability. The procurement team, impressed by the quick turnaround, assumes that the production lead time for a 500-unit order will follow a similar pattern: if one sample takes 5 days, then 500 units should take perhaps 15–20 days, accounting for the larger volume. The supplier quotes a 25-day lead time for the production order, which the procurement team accepts, believing it aligns with the sample turnaround they observed. In practice, this is often where [decisions around production timelines for custom electronics](https://ethergiftpro.uk/news/what-is-minimum-order-quantity-custom-tech-gifts-uk) start to be misjudged. The procurement team discovers, weeks later, that the production order will not ship on day 25 but rather on day 35 or 40, because the sample lead time and the production lead time are governed by entirely different operational constraints. The result is that the procurement team, believing they have accurately forecasted the delivery timeline based on the sample experience, finds themselves scrambling to explain delays to internal stakeholders or missing critical event deadlines.

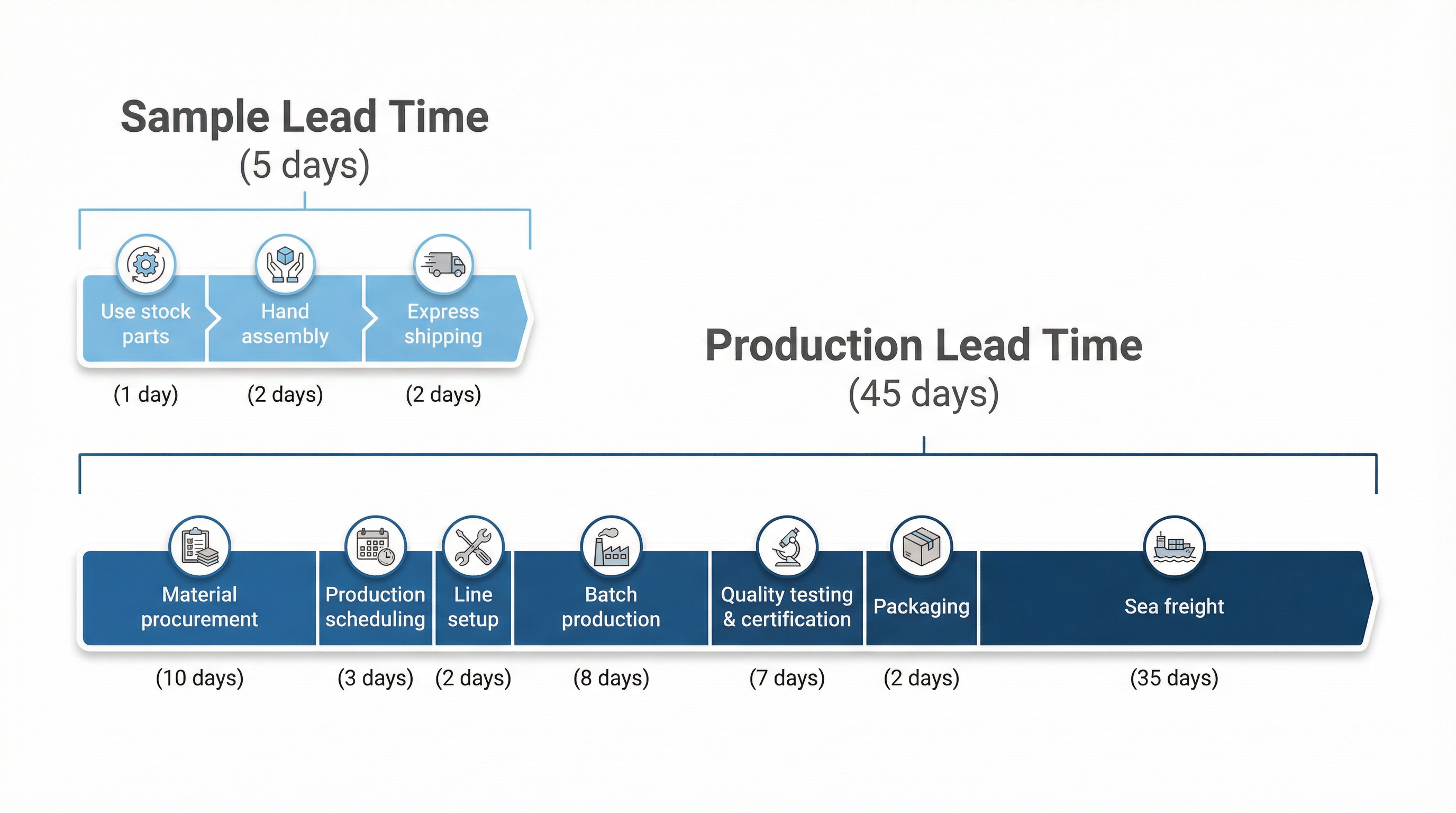

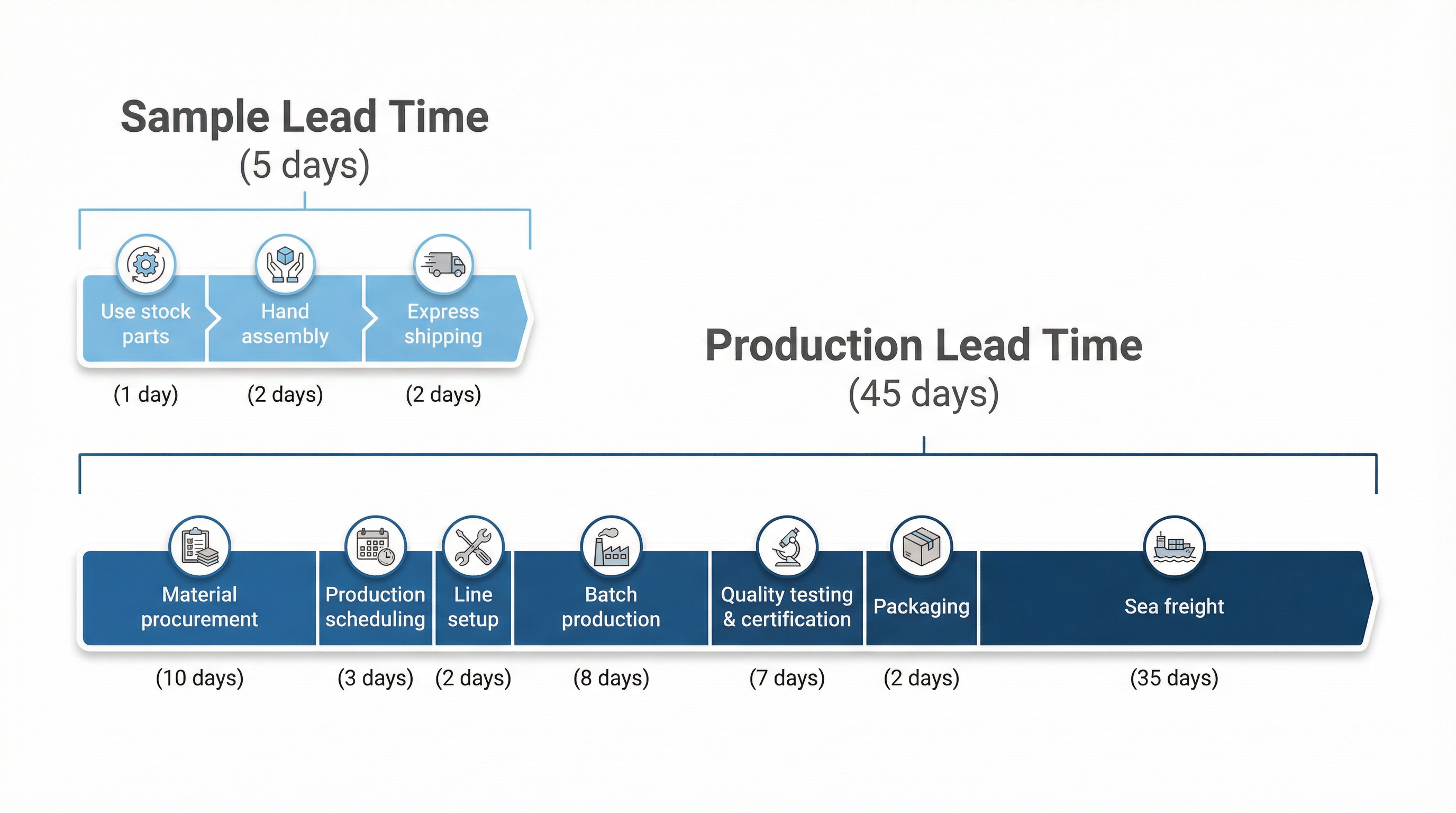

The core misunderstanding stems from treating sample production and mass production as if they operate on the same timeline, when in reality they are fundamentally different processes. Sample production is designed for speed and flexibility: the supplier prioritizes getting a prototype into the buyer's hands as quickly as possible to secure the order. To achieve this, the supplier bypasses many of the steps required for mass production. For a sample wireless charger, the supplier may hand-assemble the unit using components already in stock, skip formal testing protocols, and ship the sample via express courier without waiting for batch consolidation. The 5-day sample lead time reflects this streamlined, low-volume approach. Mass production, by contrast, requires the supplier to source raw materials in bulk, schedule production line time, conduct batch testing for regulatory compliance, and coordinate logistics for container shipment. Each of these steps introduces delays that are absent from the sample production process. The procurement team, having observed the 5-day sample turnaround, assumes that the supplier's production capability is similarly fast, when in fact the sample turnaround tells them almost nothing about the supplier's ability to deliver a 500-unit order on schedule.

A common scenario illustrates this dynamic. A procurement manager sources 500 custom-branded power banks for a corporate event scheduled for March 15. The supplier delivers a sample on January 10, five days after the initial inquiry. The procurement manager approves the sample on January 12 and places the production order on January 15, expecting delivery by February 10 based on the supplier's quoted 25-day lead time. The supplier confirms the order and begins the production process. On January 20, the supplier discovers that the custom Pantone color specified by the buyer requires a special dye that is not in stock and must be ordered from an upstream supplier. The dye arrives on January 28, eight days later than expected. Production begins on January 30, but the supplier's production line is already booked with other orders, so the power bank order is scheduled for February 5. Production completes on February 12, but the units must undergo batch testing for CE and UKCA compliance, which takes an additional five days. The units pass testing on February 17 and are ready for shipment on February 20—35 days after the order was placed, not the 25 days the procurement manager expected. The procurement manager, who planned the event logistics around a February 10 delivery, now faces a 10-day delay and must either postpone the event or source alternative gifts at a premium. The supplier was not dishonest; the 25-day lead time was a reasonable estimate for a standard order. The procurement manager, however, failed to account for the additional steps required for custom production—steps that were invisible during the sample phase because the sample was produced using stock components and expedited processes.

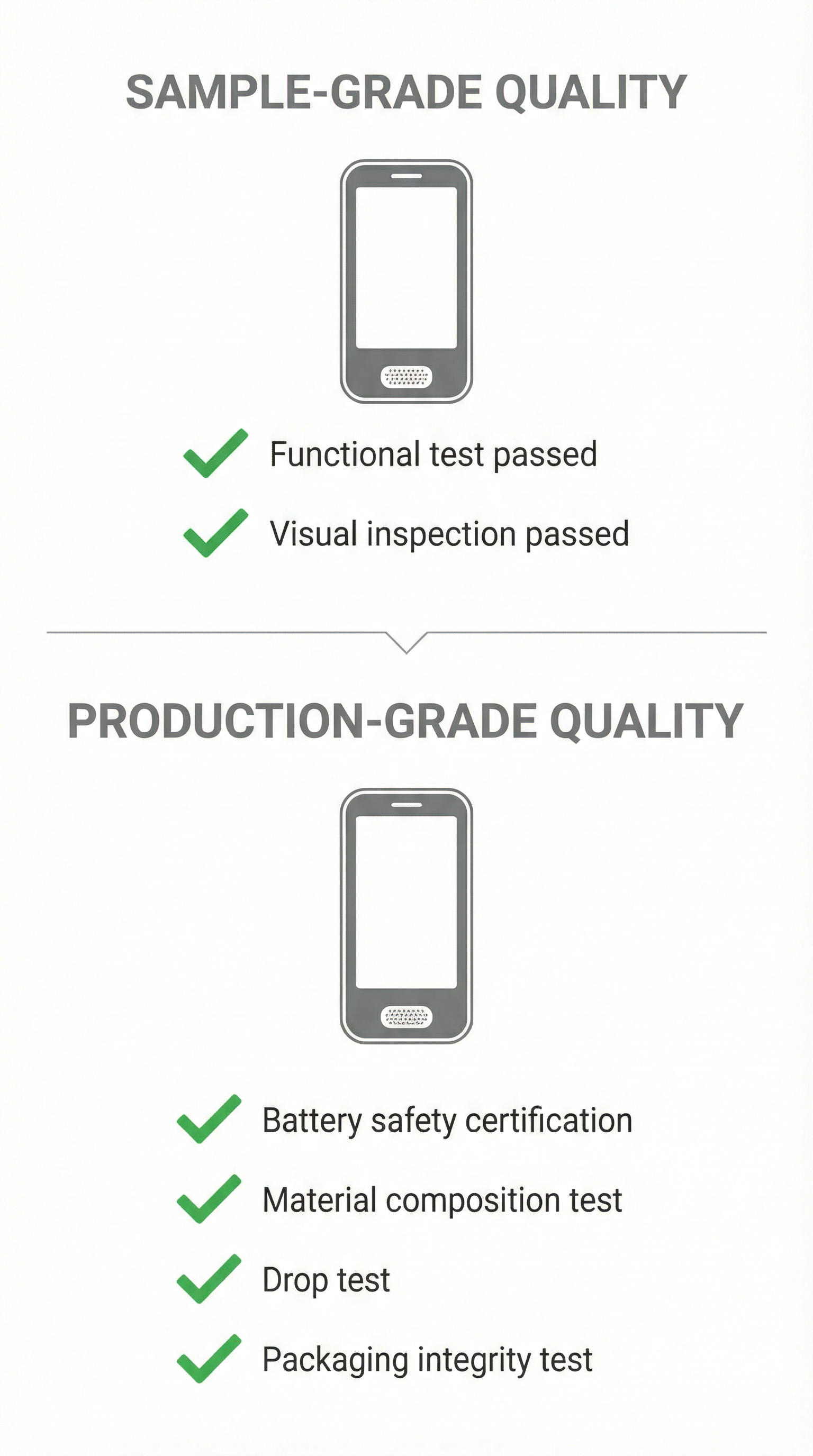

This misjudgment is compounded by the failure to distinguish between sample-grade quality and production-grade quality. When a supplier produces a sample, they are demonstrating the product's design and functionality, not its compliance with regulatory standards or its consistency across a production batch. A sample wireless charger may function perfectly when tested by the buyer, but it has not undergone the batch testing required for CE marking, UKCA certification, or RoHS compliance. For a production order, the supplier must conduct these tests on a representative sample from the production batch, and if the units fail any test, the supplier must rework the batch and retest, adding 7–14 days to the lead time. Procurement teams who assume that the sample's approval guarantees the production batch's compliance are systematically underestimating the time required for regulatory testing and the risk of test failures. A sample that passes the buyer's visual inspection and functional testing may still fail batch testing for electromagnetic compatibility (EMC), battery safety, or material composition, requiring the supplier to adjust the design, source alternative components, and repeat the testing process. This risk is particularly acute for custom electronics, where even minor design changes—such as adding a logo to the casing or changing the USB port type—can affect the product's compliance status and require additional testing.

Another layer of complexity arises from the difference between hand-assembled samples and machine-produced units. When a supplier produces a sample, they often hand-assemble the unit to ensure precision and quality, using skilled technicians who can adjust the assembly process in real time. For a production order, the supplier uses automated or semi-automated production lines, which require setup time, calibration, and operator training. If the production line is configured for a different product, the supplier must reconfigure the line for the power bank order, which takes 1–3 days depending on the complexity of the product and the extent of the design changes. Procurement teams who assume that the production process will replicate the sample assembly process are systematically underestimating the time required for production line setup and the risk of assembly errors during the initial production run. A sample that was hand-assembled in 5 days may require 2 days of line setup, 3 days of trial production to identify and correct assembly errors, and 15 days of full production, resulting in a total lead time of 20 days—four times longer than the sample lead time.

The problem is further exacerbated when procurement teams request design changes after approving the sample. A common pattern is for the buyer to approve the sample on January 12, place the production order on January 15, and then request a minor design change on January 20—perhaps adjusting the logo size, changing the packaging color, or modifying the USB cable length. The procurement team assumes that these are minor changes that will not affect the lead time, because the sample was produced quickly and the changes appear trivial. In reality, any design change after sample approval requires the supplier to produce a new sample, send it for buyer approval, and wait for confirmation before beginning production. This adds 7–10 days to the lead time, pushing the delivery date from February 10 to February 20. If the buyer requests multiple rounds of design changes, the cumulative delay can extend the lead time by 15–20 days, resulting in a delivery date of March 1 or later. The supplier, who quoted a 25-day lead time based on the assumption that the design would be finalized after sample approval, is now facing a 40-day lead time due to the buyer's post-approval changes. The procurement team, who believed that the sample approval locked in the design and the lead time, discovers too late that design changes after approval reset the production timeline and introduce new risks of delay.

Procurement teams who wish to avoid this misjudgment must recognize that sample lead time and production lead time are governed by different constraints and should not be used interchangeably. The sample lead time reflects the supplier's ability to produce a single prototype using expedited processes and stock components. The production lead time reflects the supplier's ability to source raw materials, schedule production line time, conduct batch testing, and coordinate logistics for a multi-unit order. A 5-day sample lead time does not predict a 15-day production lead time for 500 units; it predicts only that the supplier can produce a prototype quickly under ideal conditions. To accurately forecast the production lead time, procurement teams must ask the supplier to break down the lead time into its component steps: raw material procurement (7–10 days), production line setup (2–3 days), production (10–15 days), batch testing (5–7 days), and logistics (3–5 days). This breakdown reveals the steps that were bypassed during sample production and provides a more realistic estimate of the total lead time. Procurement teams who rely on sample lead time as a proxy for production lead time are systematically underestimating delivery timelines and increasing the risk of missing critical deadlines.

The distinction between sample-grade logistics and production-grade logistics further amplifies this misjudgment. When a supplier ships a sample, they typically use express courier services—DHL, FedEx, or UPS—which deliver the package within 3–5 days regardless of the destination. The procurement team receives the sample quickly and assumes that the production order will follow a similar shipping timeline. For a production order of 500 units, however, the supplier uses sea freight or consolidated air freight, which takes 30–40 days for sea shipment or 7–10 days for air freight, plus an additional 3–5 days for customs clearance and inland transportation. The procurement team, who experienced a 5-day sample delivery, assumes that the production order will arrive within 7–10 days of shipment, when in fact the logistics timeline alone adds 10–45 days to the total lead time depending on the shipping method. This logistics gap is rarely disclosed upfront because suppliers quote lead times based on "ex-factory" terms—the date the goods leave the factory—not the date the goods arrive at the buyer's warehouse. Procurement teams who fail to clarify whether the quoted lead time includes logistics are systematically underestimating the total delivery timeline by 10–45 days.

Another critical factor is the difference between sample-level component sourcing and production-level component sourcing. When a supplier produces a sample, they use components that are already in stock or can be sourced quickly from local distributors. For a sample wireless charger, the supplier may use a generic charging coil, a standard USB-C port, and an off-the-shelf circuit board, all of which are available within 1–2 days. For a production order, however, the buyer often requests custom specifications: a specific charging coil model for faster charging, a branded USB-C port with the company logo, or a custom circuit board layout to accommodate additional features. These custom components require longer procurement lead times—7–14 days for custom coils, 10–15 days for branded ports, and 15–20 days for custom circuit boards—and any delay in component delivery pushes back the entire production schedule. The procurement team, who approved a sample that used stock components, assumes that the production order will use the same components and follow the same timeline, when in fact the custom specifications they requested have introduced new procurement dependencies that extend the lead time by 15–30 days.

The final layer of complexity arises from the difference between sample-level quality control and production-level quality control. When a supplier produces a sample, they conduct visual inspection and basic functional testing to ensure the unit works as intended. For a production order, the supplier must conduct batch-level quality control: random sampling from the production batch, functional testing of multiple units, stress testing for durability, and compliance testing for regulatory standards. If any unit in the sample batch fails testing, the supplier must identify the root cause, adjust the production process, and retest the batch, adding 5–10 days to the lead time. Procurement teams who assume that the sample's approval guarantees the production batch's quality are systematically underestimating the time required for batch-level quality control and the risk of quality failures during production. A sample that passes all tests may still reveal quality issues when produced at scale—such as inconsistent assembly, component variations, or packaging defects—requiring the supplier to halt production, correct the issue, and restart the production run. This quality control gap is particularly acute for custom electronics, where even minor variations in component specifications or assembly processes can affect the product's functionality, safety, or compliance status.

Procurement teams who recognize these distinctions can avoid the sample-to-production misjudgment by treating sample lead time and production lead time as separate, non-comparable metrics. The sample lead time reflects the supplier's prototyping capability and responsiveness, which are valuable for evaluating supplier engagement and design flexibility. The production lead time reflects the supplier's manufacturing capability, supply chain coordination, and quality control processes, which are the true determinants of delivery reliability. By requesting a detailed production timeline breakdown during the quotation phase—before placing the order—procurement teams can identify the hidden steps that were bypassed during sample production and build realistic delivery expectations that account for raw material procurement, production line setup, batch testing, logistics, and quality control. This approach transforms the sample phase from a misleading predictor of production timelines into a valuable design validation step that informs, but does not dictate, the production schedule.