Latest News & Insights

Discover expert insights on corporate gifting, technology trends, and business relationship building.

Explore Our Expert Content

From technical deep-dives to procurement strategies, find the knowledge you need to make informed decisions.

Why Your Custom Packaging Always Arrives Late: The Hidden Production Dependencies in Branded Power Bank and USB Drive Orders

Understanding why custom packaging for branded power banks and USB drives creates hidden production dependencies that can add weeks to delivery timelines.

Why Your Sample Approval Always Takes Two Weeks Longer Than Expected: The Hidden Bottlenecks in Custom Power Bank and USB Drive Projects

Procurement teams consistently underestimate the complexity of internal approval chains and their cascading impact on production scheduling. Understanding why sample approval takes longer than planned reveals hidden bottlenecks that can transform a ten-day delay into a six-week delivery setback.

Why Your Full-Size Logo Gets Rejected: Understanding Print Area Constraints on Custom Power Banks and USB Drives

Understanding why your full-size logo gets rejected on custom power banks and USB drives. Learn how print area constraints affect the customization process and how to avoid costly design revision cycles.

Why Your Pantone-Specified Brand Colour Looks Different on Every Custom Power Bank and Wireless Charger

When a procurement team specifies a Pantone colour code for their custom tech gifts, they naturally expect the finished products to display that exact shade. The brand guidelines are clear, the Panton...

Why Your High-Resolution Logo Still Prints Blurry on Custom Power Banks and USB Drives

Understanding the critical difference between raster and vector file formats, and why artwork preparation is a key decision variable in the customization process for custom tech gifts.

Mockup Approval vs Production Reality: Why Your Custom Tech Gift Looks Different from the Digital Preview

UK procurement teams often mistake mockup approval for production guarantee. Learn why digital previews cannot predict actual customization results and how to set realistic quality expectations.

Cross-Border Lead Time Reset: Why Transit Time Quotes Underestimate Actual Delivery by 150% for Custom Tech Gifts

Procurement teams often misinterpret supplier-quoted Transit Time (21 days) as Cumulative Lead Time, systematically underestimating actual delivery by 34 days (162%). This misjudgment stems from a definitional gap: Transit Time measures only cargo in motion, excluding pre-shipment and post-arrival stages that add 30-40 days to cross-border custom tech gift orders.

Supplier Transition Lead Time Reset: Why First Orders Take 50-100% Longer Than Quoted for Custom Tech Gifts

Procurement teams switching to new suppliers of custom tech gifts often assume quoted lead times apply to first orders. In reality, onboarding complexity, specification clarification, and quality validation extend first-order lead times by 50-100%, causing delivery delays and production disruptions.

Peak Season Lead Time Misjudgment: Why "Normal Lead Time Plus Buffer" Fails for Q4 Custom Tech Gift Orders

Procurement teams planning Q4 custom tech gift orders typically apply a linear buffer to normal lead times—assuming peak season extends delivery by 50%—but this approach systematically underestimates actual lead times by 200-300%. The misjudgment stems from treating supplier capacity as elastic when it is finite, failing to account for non-linear queue dynamics, supplier prioritization logic, and capacity reservation by competitors.

Why Multiple Custom Tech Gift Orders Take Longer Than You Think: The Hidden Cost of Production Line Sequencing

When procurement teams place multiple custom tech gift orders simultaneously, they often assume that all orders can proceed in parallel and that the total delivery timeline equals the longest individual lead time. In reality, multiple orders compete for the same production resources, requiring sequential processing, production line changeovers, priority sequencing, and quality inspection coordination. This misjudgment routinely causes procurement teams to underestimate total delivery timelines by 30–50%, leading to missed event deadlines and stakeholder dissatisfaction.

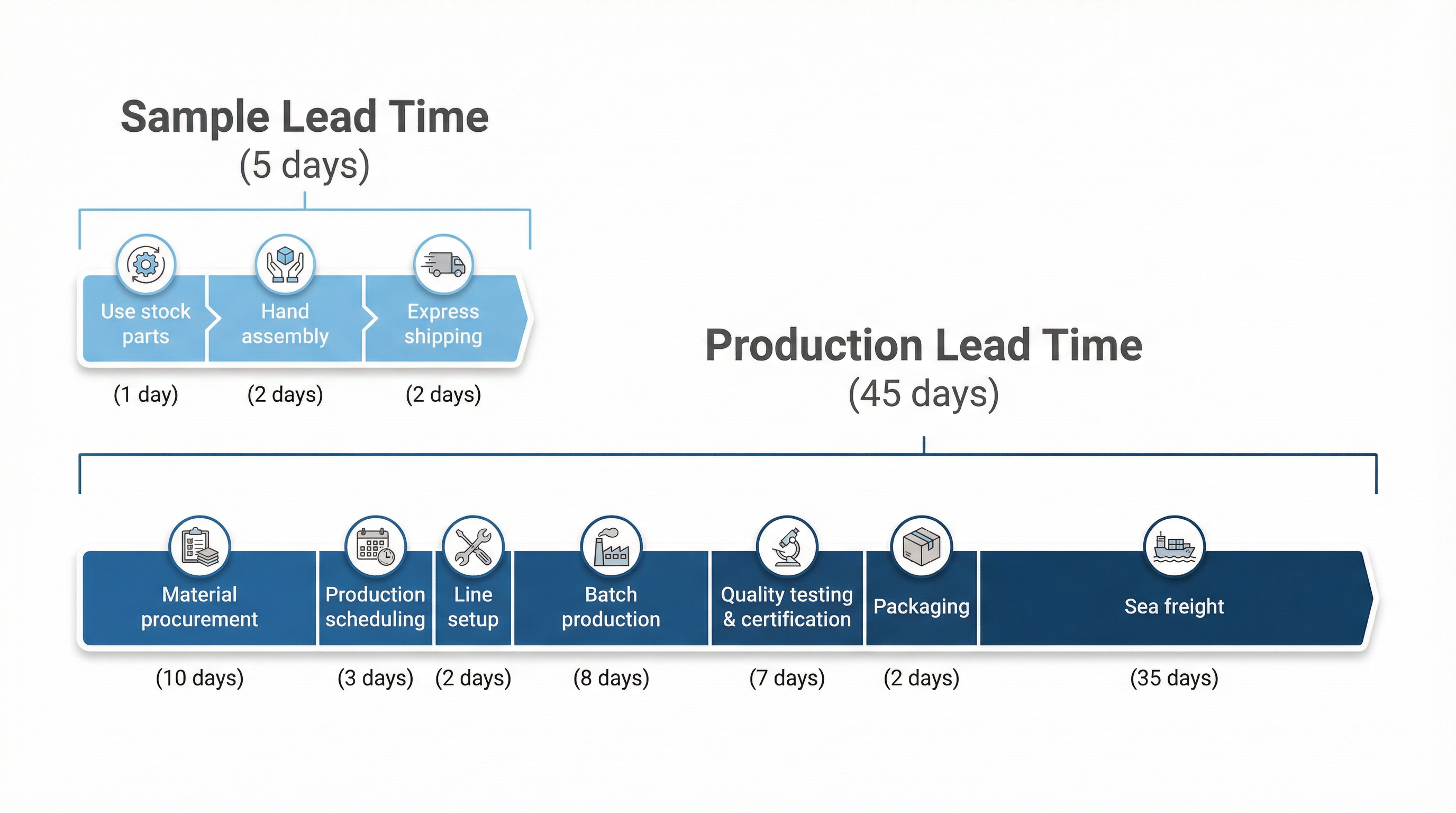

Sample Lead Time vs Production Lead Time: Why Fast Prototyping Does Not Predict Mass Production Timelines

Procurement teams often extrapolate production timelines from sample lead times, assuming that if a supplier delivers a prototype in 5 days, a 500-unit order will take proportionally longer. In reality, sample production and mass production operate under entirely different constraints, and this misjudgment routinely causes procurement teams to underestimate delivery timelines by 30–50%.

Multi-Batch Orders and Cumulative Lead Time: Why Splitting Orders Often Extends Total Delivery Time

Procurement teams often split large orders into smaller batches to manage risk, expecting the total timeline to mirror the lead time of a single batch, but each batch requires its own setup, sampling, approval, and production cycle, creating cumulative delays that extend total delivery time far beyond what a single consolidated order would require.